Vapor injection in scroll compressors represents a significant advancement in refrigeration systems and heat pump systems

What Is Liquid Injection and Why Is It Used?

Just as vapor injection boosts performance during tough weather, liquid injection is another clever technique designed to protect the compressor—especially under demanding conditions. Unlike vapor injection, which adds refrigerant as a gas, liquid injection introduces a small amount of liquid refrigerant directly into the compressor.

Why go liquid? When a compressor works hard—think low-temperature freezer applications or extreme operating loads—it can generate significant heat. Left unchecked, this heat can break down compressor oil, threatening both reliability and lifespan.

Here’s how liquid injection works in a nutshell:

- A controlled quantity of refrigerant is taken from the system’s liquid line and sent through a metering device (often an injector valve) into the compressor itself.

- In scroll compressors, this refrigerant is usually injected right into the scroll elements, cooling critical parts from within.

The result is cooler compression temperatures, happier lubrication, and a compressor that’s far less likely to call it quits under stress. It’s yet another way modern HVAC systems tackle the heat, ensuring your equipment runs smoothly, even when conditions are less than ideal.

Understanding Refrigerant States in the Cycle

In the refrigeration cycle, the state of the refrigerant—whether it’s a vapor or a liquid—is determined primarily by two factors: pressure and location within the system.

- High-pressure side: After the compressor, the refrigerant is under high pressure as it moves through the condenser. In this stage, it typically transitions from a hot vapor into a liquid as it releases heat.

- Low-pressure side: After passing through the expansion valve, the refrigerant is at a lower pressure and moves into the evaporator as a cold liquid. As it absorbs heat, it turns back into a vapor.

Essentially, in the evaporator and before the compressor, the refrigerant is mostly a vapor. After compression and condensation, it becomes a liquid before repeating the cycle. Recognizing where the refrigerant is liquid or vapor within these stages is key to understanding how vapor injection improves system efficiency.

Visualizing High-Pressure vs. Low-Pressure Sides

Imagine a baseball diamond: If you draw a straight line from home plate up to second base, you create a handy visual split. On one side of that line, you’ll find the high-pressure components of the refrigeration system—like the compressor and condenser. On the other, everything operates at low pressure, including the evaporator and suction line. This simple visualization helps technicians and homeowners alike quickly understand which parts of the system are working under greater strain and which ones are handling cooler, lower-pressure refrigerant.

How Pressure and Temperature Change in the Refrigeration Cycle

To understand how pressure and temperature move through a refrigeration system, let’s break it down step by step—think of it like a relay race for refrigerant:

- Compressor: The refrigerant starts its journey in the compressor, entering as a cool, low-pressure vapor. Once inside, the compressor squeezes this vapor, raising both its pressure and temperature dramatically. Now, the refrigerant leaves as a hot, high-pressure vapor and gets ready for its next lap.

- Condenser: Next stop, the condenser. Here, the vapor is still under high pressure and high temperature. But as it passes through the condenser coils—often cooled by air or water—the refrigerant sheds heat to the surrounding environment. As it cools down, it condenses into a high-pressure liquid.

- Metering Device (Expansion Valve): The condensed refrigerant then encounters a metering device, which acts like a bouncer at an exclusive club—regulating exactly how much can pass through. By forcing the liquid refrigerant through a small orifice, it causes a dramatic pressure drop. This drop in pressure also leads to a significant temperature decrease.

- Evaporator: Finally, the chilled, low-pressure refrigerant enters the evaporator coils. Here, it absorbs heat from the environment—whether it’s your living room or a freezer compartment—causing the refrigerant to evaporate and return to a vapor state. Now it’s a low-pressure, low-temperature vapor once again, ready to cycle back to the compressor and start the process over.

In summary, the refrigeration cycle orchestrates the refrigerant’s pressure and temperature in a repeating loop: compress high, condense and cool, expand and chill, then absorb ambient heat. This continuous see-sawing of pressure and temperature is what keeps your air conditioning or refrigeration system running efficiently and reliably.

How Refrigerant Moves Through Each Main Component

Let’s take a closer look at what actually happens to the refrigerant as it flows through the heart of your cooling system—compressor, condenser, metering device, and evaporator.

- Compressor: The journey starts here, where the refrigerant arrives as a low-pressure, low-temperature vapor. The compressor’s job? Squeeze that vapor, raising its pressure and temperature. Imagine giving an overstuffed suitcase one last push—everything gets packed tighter, and things heat up from the effort.

- Condenser: Next stop: the condenser. Here, the now-hot and pressurized vapor travels through coils—often cooled by a fan—where it releases its unwanted heat to the outside air. As the refrigerant sheds heat, it shifts from a vapor to a high-pressure liquid. Think of it like a steaming mug cooling off on a cold countertop.

- Metering Device: After that, the metering device (sometimes a TXV or capillary tube) steps in. Its role is similar to the nozzle on a garden hose, precisely controlling how much liquid refrigerant enters the next stage. It also drops the pressure of the refrigerant, prepping it for efficient heat absorption in the evaporator.

- Evaporator: Finally, the refrigerant enters the evaporator as a cool, low-pressure liquid. Here, it picks up heat from the surrounding air (or water, depending on the system), evaporating into a vapor again. This is where the magic of cooling happens—the air passing over the evaporator coil loses its heat to the refrigerant, and voila, your space gets more comfortable. The cycle then begins anew as the refrigerant heads back to the compressor.

Every step in this process plays a crucial part in keeping your indoor climate just right—whether you’re braving a sweltering Miami summer or a surprise cold snap in the Sunshine State.

Metering Device: Regulating Refrigerant Flow

A metering device acts as the gatekeeper for refrigerant entering the evaporator. Its main job is to precisely control how much refrigerant is allowed through, adjusting to meet the system’s cooling demands. By doing so, it creates the necessary pressure drop that allows the refrigerant to evaporate and absorb heat efficiently.

This device also plays a critical role in maintaining consistent operation by monitoring superheat levels at the evaporator’s outlet. By fine-tuning the flow, it helps safeguard the compressor from liquid refrigerant, ensures stable temperatures, and keeps your HVAC system running smoothly—delivering reliable comfort even as conditions change.

The Four Key Components of the Refrigeration Cycle

At the heart of every cooling system—no matter its size—you’ll find the same four essential parts: the compressor, condenser, metering device, and evaporator. Let’s break down the starring roles they play in the refrigeration cycle:

- Compressor

Think of this as the engine room. The compressor draws in refrigerant vapor at low pressure and low temperature, then squeezes it to boost both pressure and temperature. This step preps the refrigerant for the journey ahead and helps drive circulation throughout the system. - Condenser

Once the refrigerant leaves the compressor, it travels to the condenser. Here, the job is to shed heat. The condenser cools the hot, high-pressure vapor, transforming it into a cooler liquid by radiating heat away—sort of like a car radiator that expels engine warmth into the air. - Metering Device

This component controls the flow. The metering device (often a thermostatic expansion valve or capillary tube) regulates how much liquid refrigerant enters the evaporator. By creating a controlled pressure drop, it ensures the system stays balanced and efficient, adapting to different cooling demands as needed. - Evaporator

Finally, the evaporator is where the magic of cooling happens. Here, the refrigerant absorbs heat from the surrounding air or fluid, causing it to boil and vaporize. This cools the space or substance, and the now low-pressure vapor heads back to the compressor—ready for another lap through the cycle.

Each of these four workhorses plays a vital part in keeping conditions comfortable, efficient, and reliable, whether you’re chilling a small office or powering through a summer heatwave in the Sunshine State.

Understanding Scroll Compressors

What is a Scroll Compressor?

A scroll compressor is a type of compressor that utilizes two interleaved

spiral-shaped scrolls to compress refrigerant. One scroll remains fixed, while the other orbits around it. As the orbiting scroll moves, it traps pockets of vapor refrigerant and progressively reduces their volume, thereby increasing the pressure. Unlike a reciprocating compressor, which uses pistons, the scroll compressor operates with a continuous, smooth motion, leading to lower noise and vibration levels. This design is particularly advantageous in refrigeration and heat pump applications where quiet and reliable operation is crucial. The inherent simplicity and efficiency of the scroll design have made it a popular choice in modern compressor technology.

How Scroll Compressors Function

The functionality of a scroll compressor hinges on the interaction between its two spiral-shaped scrolls. Vapor refrigerant enters the compressor at a low pressure and is drawn into the pockets formed between the scrolls. As the orbiting scroll moves, these pockets progressively shrink, compressing the refrigerant. This continuous compression process, enhanced by an injection system, results in a smooth, pulsation-free discharge of high-pressure. vapor refrigerant. The efficiency of the scroll compressor is largely due to the minimal clearance volume and the absence of valves, which reduces losses associated with re-expansion. This makes the scroll compressor a very reliable device, particularly useful in refrigeration.

Advantages of Scroll Compressors in Refrigeration

Scroll compressors offer several distinct advantages in refrigeration applications. In particular, they offer benefits like:

- Lower noise and vibration compared to reciprocating compressor designs due to their smooth, continuous operation.

- Increased overall compressor efficiency resulting from the absence of valves, which reduces mechanical losses.

Scroll compressors are also known for their reliability and durability due to the simplicity of their design and fewer moving parts, making them ideal for vapor-injected compressors. These characteristics make them well-suited for a wide range of refrigeration system applications, from residential refrigerators to large-scale industrial cooling systems. Their ability to handle liquid slugging better than some other compressor types also contributes to their robustness in demanding environments, improving the refrigeration cycle.

The Role of Vapor Injection

What is Vapor Injection?

Refrigerant injection, commonly referred to as air-source heat pump systems. vapor injection,

is a method employed to enhance the performance and reliability of heat pump systems and refrigeration systems, especially when operating under challenging ambient conditions. The technique involves redirecting a portion of the refrigerant from the condenser outlet back into the compressor, specifically into an intermediate stage of the compression process. This process allows the scroll compressor to operate more efficiently. Ongoing research in injection technology for heat pump applications focuses on component optimization, advanced control strategies, and comprehensive compressor and refrigeration system modeling to maximize the benefits of vapor injection and improve compressor efficiency.

Benefits of Vapor Injection in Scroll Compressors

One of the primary benefits of vapor injection in scroll compressors is the ability to achieve higher heating capacities by increasing refrigerant circulation in the refrigeration system. The increased refrigerant mass flow rate can enhance convective heat transfer coefficients, making the heat exchange process more efficient. Because a portion of the refrigerant is injected into the system, often utilizing an economizer for better efficiency. scroll compressor at an intermediate pressure, less compression work is required compared to a compressor without vapor injection, resulting in improved compressor efficiency. Moreover, the incorporation of liquid injection can significantly improve efficiency. refrigerant injection can effectively reduce the discharge temperature of the compressor, contributing to enhanced reliability and longevity of the compressor. The refrigeration cycle Refrigeration technology benefits greatly from advancements in vapor-injected compressors. vapor injection.

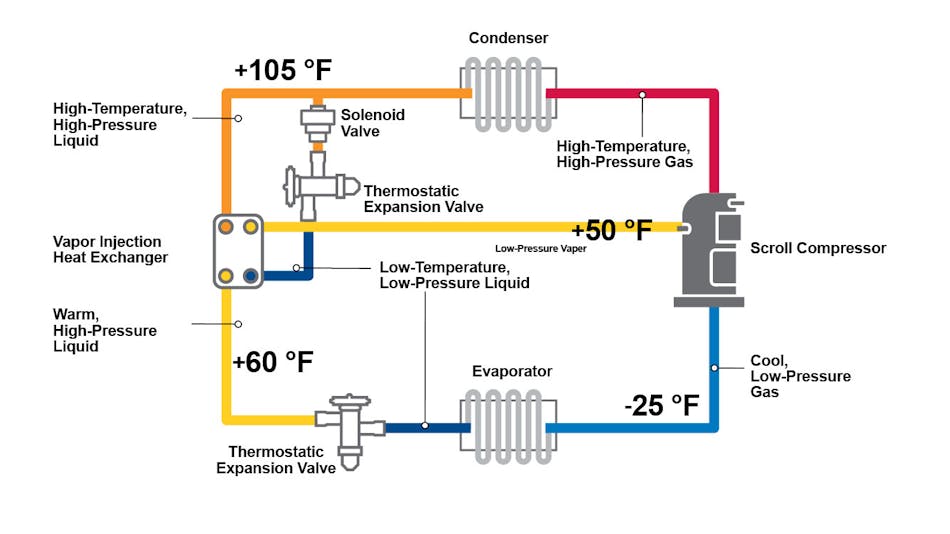

Vapor Refrigerant Injection Process

The vapor refrigerant injection process involves piping refrigerant from the system liquid line, through an injector valve, directly into the scroll compressor. In scroll compressors, the refrigerant is injected directly into the scroll design elements. Without this cooling effect provided by the injection process, the compression components can overheat, potentially causing oil breakdown and leading to compressor failures. A heat exchanger is often utilized to provide subcooling to the refrigerant before it enters the evaporator. A small amount of refrigerant is evaporated and superheated above its boiling point, often utilizing an injection system for improved performance. This superheated vapor refrigerant is then injected mid-cycle into the scroll compressor and compressed to discharge pressure, optimizing the refrigeration cycle and ensuring optimal compressor performance in the refrigeration system.

Refrigeration Cycle with Vapor Injection

Overview of the Refrigeration Cycle

The conventional refrigeration cycle relies on four essential components. These components are critical to the process:

- A compressor

- A condenser

The refrigeration cycle also requires a metering device and an evaporator. Refrigerant enters the compressor as a low-pressure (LP), low-temperature (LT), superheated vapor refrigerant and exits as a high-pressure (HP), high-temperature (HT) vapor, crucial for vapor compression systems. vapor refrigerant. The compressor mechanically compresses the refrigerant gas, reducing its volume and raising its temperature. From the compressor, the hot, pressurized refrigerant gas enters the condenser, designed to reject heat and return the refrigerant to its condensing temperature. As it rejects heat, the condenser converts the vapor refrigerant to a sub-cooled liquid. The metering device regulates the flow of refrigerant into the evaporator and causes a pressure drop. The cold liquid refrigerant mixes with vapor refrigerant, causing saturation as it vaporizes in the evaporator, absorbing heat. The low-pressure superheated vapor refrigerant gas returns to the injection compressor for further compression. compressor, restarting the refrigeration process. The refrigeration system works by circulating refrigerant.

Integration of Vapor Injection Technology

The integration of vapor injection technology into a scroll compressor with vapor injection Involves introducing liquid injection to enhance the overall efficiency of the system. vapor refrigerant at an intermediate stage of the compression process. Typically, this is achieved through an injection port located strategically within the scroll design. The vapor injection process allows for enhanced cooling of the compressor during operation and can improve the overall compressor efficiency, as the compressor does not have to work as hard. This injection process is particularly useful in systems that operate with high compression ratio, where the temperature of the refrigerant can become exceedingly high. The injection mass flow rate is carefully controlled to optimize the cooling effect and maximize the performance of the refrigeration cycle. By integrating vapor injection, engineers can extend the operating range of scroll compressor systems, especially in demanding refrigeration applications.

Impact on Energy Efficiency

The incorporation of vapor injection technology significantly impacts the energy efficiency of refrigeration systems. By injecting vapor refrigerant into the scroll compressor, the discharge temperature is reduced, and the overall compressor efficiency is enhanced, decreasing energy consumption. The vapor injection process also enables a higher refrigerant mass flow rate, which improves the cooling capacity of the refrigeration system without a proportional increase in energy input. Another approach called enhanced vapor injection (EVI) increases the efficiency of the injection compressor. refrigeration capacity and, in turn, the efficiency of the refrigeration system. Moreover, vapor injection allows the scroll compressor to operate more efficiently under extreme conditions, such as high ambient temperatures or low evaporating temperatures. This leads to substantial energy savings and reduced operating costs in heat pump system and refrigeration system applications. By optimizing the injection mass flow rate and the timing of the vapor injection, even greater energy efficiency gains can be achieved.

Applications of Vapor-Injection Scroll Compressors

Commercial Refrigeration Systems

Vapor-injected scroll compressors are widely used in commercial refrigeration systems. The ability of scroll compressors with vapor to enhance compressor efficiency and cooling capacity makes them ideal for applications such as supermarket display cases, walk-in coolers, and other commercial refrigeration units. The vapor injection technology helps maintain stable temperatures and reduces energy consumption, leading to lower operating costs for businesses. In these refrigeration systems, the use of refrigerant is optimized through vapor injection. This makes the injection process particularly valuable in environments where consistent and reliable cooling is essential.

Industrial Applications

Beyond commercial refrigeration, vapor injection scroll compressors are also employed in various industrial applications that require precise temperature control and high reliability. The ability of vapor injection technology to handle demanding conditions and maintain stable performance makes them well-suited for industrial cooling processes, such as in the food and beverage industry, chemical processing, and pharmaceutical manufacturing. In these settings, scroll compressors with vapor can provide efficient cooling solutions for large-scale refrigeration systems, ensuring product quality and process stability. The effectiveness of refrigerant management in such applications highlights the importance of efficient compressor efficiency and robust compressor design.

Future Trends in Refrigeration Technology

As refrigeration technology continues to evolve, vapor injection is poised to play an increasingly significant role in shaping future advancements. Ongoing research and development efforts are focused on optimizing the vapor injection heat process. vapor refrigerant injection process, exploring new refrigerant options, and integrating advanced control strategies to further enhance the performance of vapor injection scroll compressors. With the growing emphasis on energy efficiency and environmental sustainability, the use of vapor injection is expected to expand across various refrigeration applications, contributing to more efficient and environmentally friendly cooling solutions. The future of scroll compressors with vapor will bring more complex compressor design.

Conclusion

Summary of Key Points

In summary, vapor injection in scroll compressors enhances refrigeration system efficiency. By strategically injecting vapor refrigerant into the scroll compressor during the compression process, engineers can enhance compressor efficiency, increase cooling capacity, and improve overall system reliability. Vapor injection technology has found applications in various sectors, including commercial refrigeration, industrial processes, and heat pump systems. The integration of vapor injection technology offers substantial benefits in terms of energy savings and operational performance.

Future Prospects for Vapor Injection Technology

The future prospects for vapor injection technology in refrigeration are promising. With ongoing research and development, we can expect further advancements in compressor design, control strategies, and refrigerant options. These innovations will pave the way for even more efficient and sustainable cooling solutions, addressing the growing demand for environmentally friendly refrigeration. The use of variable speed compressors combined with vapor injection, optimized through advanced control algorithms, will lead to significant improvements in energy efficiency and performance.

Final Thoughts on Scroll Compressors in Refrigeration

Scroll compressors with vapor are a reliable and efficient solution. Their smooth operation, compact design, and ability to handle demanding conditions make them a popular choice among engineers and system designers. As refrigeration technology The technology continues to advance, particularly with the integration of air source heat pumps. scroll compressors with vapor are expected to remain a key component in future cooling systems, contributing to more sustainable and energy-efficient solutions. The evolution of scroll design will certainly make the refrigeration cycle more reliable.